Your New Boss May Not Really Understand Safety | Part 2

This article is apart of our “Tools For Building a Foundation in Safety” series by Luke Contos. We highly recommend reading Part 1, which can be found here.

Part 2.

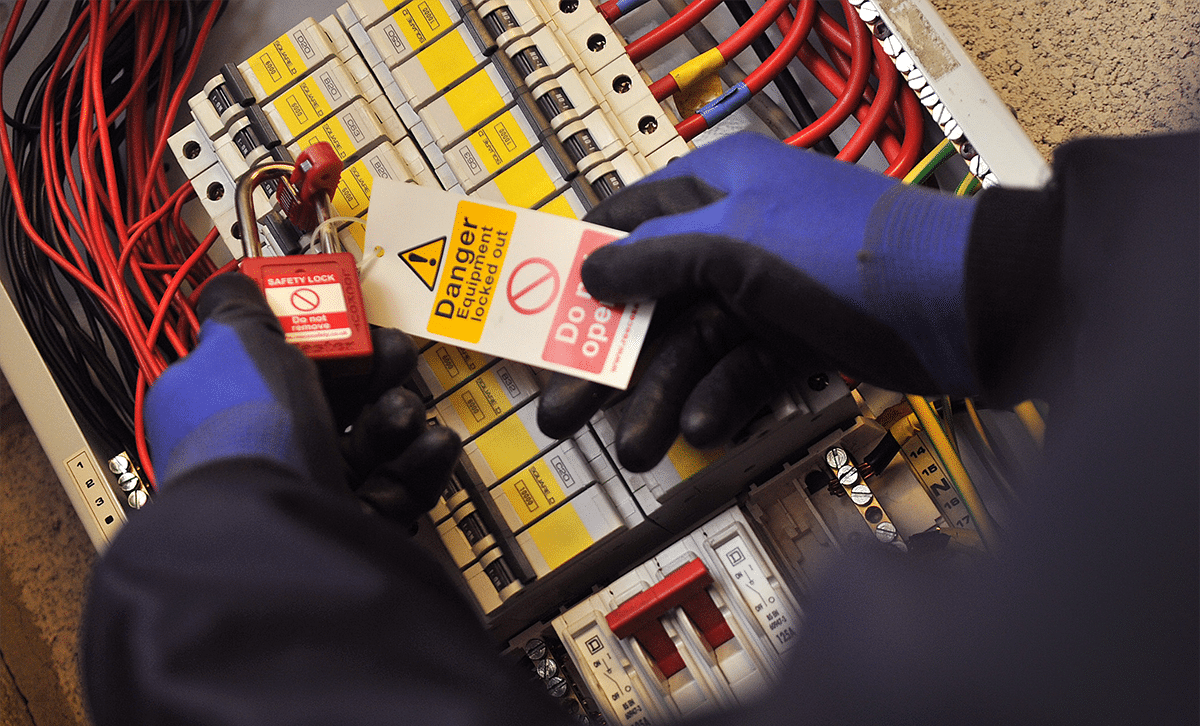

Second, as soon as practical, begin the training and implementation on some form of shop-floor level risk assessment, such as Task Based Risk Assessment (TaBRA). Why is this work so critical? Well let’s repeat the question, does every maintenance procedure, equipment down time, etc. have a work instruction or procedure associated with it? No, it would be impossible to anticipate every possible equipment or process failure scenario (before it happens) and assess and address the hazards associated with each scenario.

So by using the expertise of a cross functional team of employees, they can:

- capture each step / element of all tasks to be performed;

- identify the hazards and risks associated with each task (task-hazard pair); and

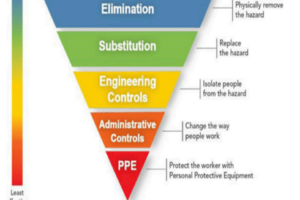

- with the high risk ‘task-hazard pairs’, implement the appropriate levels of controls (i.e., elimination, substitution, engineering controls, administrative controls, and PPE).

The benefits of building the risk assessment expertise within the work force is that it:

- Helps to drive a better employee/contractor understanding of hazard recognition and reduction;

- Builds team work and a safety culture within the workforce; and

- Reduces the potential for serious injuries and fatalities.

Summary

The two-pronged approach of:

- Teaching in layers what a proactive safety program is comprised of will hopefully help drive a greater acceptance of the elements in Table 1 rather than just managing safety around TRIR/DART and regulatory compliance; and

- Start of risk assessment process will hopefully lead to implementing systems and processes.

Lastly, the direct costs of a serious injury (i.e., medical, regulatory, legal) are often known, but may not totaled, visible, or a attributed to a particular injury. To demonstrate the true cost of accident, the indirect costs (i.e., strikes, lower productivity or quality attributed to the accident, absenteeism) need to be estimated and added into the cost of an accident.

It is never easy to assume a role with greater responsibilities, but by focusing on teaching for the long term and starting hazard identification and reduction, a stronger safety program can be built during these challenging times.

If you have questions or need help regarding distracted driving or anything safety related, please reach out to FDRsafety.