Why Another Tool Is Needed to Reduce Safety Risks

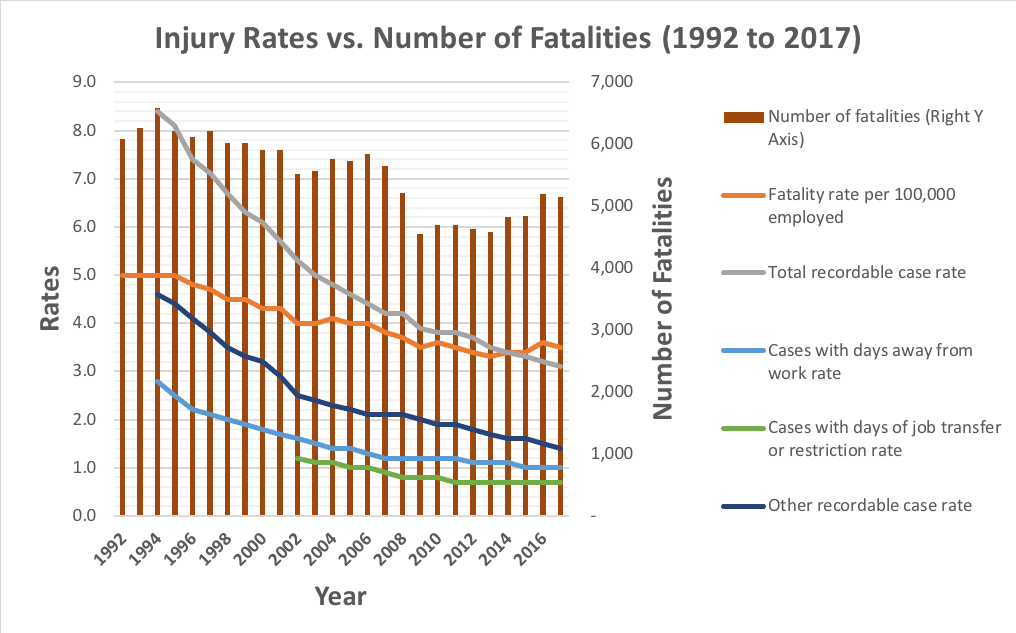

Since 1992, US businesses, governmental agencies, and industry have substantially reduced the number of recordable injuries. As shown by the Bureau of Labor Statistics data in Figure 1 and Table 1, most all

of the major safety metrics below have demonstrated substantial improvement over the past 25 years.

Below have demonstrated substantial improvement over the past 25 years.

Figure 1. Bureau of Labor Statistics Safety Data

| Rate | Rate Change Over Time Period | Percent Change |

| TRIR (Total Record Incident Rate) | 8.4 to 3.1 | 63% decrease |

| Total rate (Case rate for days away Since 1992, US businesses, governmental agencies, and industry have substantially reduced the number of recordable injuries. As shown by the Bureau of Labor Statistics data in Figure 1 and Table 1, most all of the major safety metrics from work + Case rate for days of job transfer or restriction) | 3.6 to 1.6 | 58% decrease |

| Cases with days away from work | 2.8 to 1 | 64% decrease |

| Cases with days of job transfer or restriction rate | 1.2 to 0.7 | 42% decrease |

| Other recordable cases | 4.6 to 1.4 | 70% decrease |

| Fatality rate | 5.0 to 3.5 | 30% decrease |

Table 1. Safety Metric Rate Change

However, when looking at the data in Figure 1 and Table 1, the fatality rate and the number of fatalities show only a small improvement. In addition, there is more variability in the fatality rate than any of the other safety metrics.

Most importantly it shows that with all the investments that have been made in safety (i.e., equipment, training, programs), we may not be identifying and targeting the hazards and exposures that can most often lead to serious injuries and fatalities (SIFs).

What is coming into clearer view for many safety and risk management professionals is that existing safety methods/tools for injury reduction [i.e., Job Safety Analyses (JSAs), Behavior Based Safety (BBS) programs, Standard Work (standard operating procedures)] generally focus on routine exposures to hazards identified in routine tasks. These tools, as well intentioned as they are, DO NOT and CAN NOT predict the exposures and hazards in non-routine work that can lead to a SIF.

The Need for Task Based Risk Assessment (TaBRA)

TaBRA has been created to be a dynamic tool that can focus on non-routine or non-standard tasks, tasks that have high variability and are often unique. These tasks are often found in maintenance or other non-standard work, where JSAs, BBS, etc. cannot be efficient or effective in their implementation.

TaBRA:

- Is an OSHA recognized, industry consensus method (ANSI B11) designed to help reduce SIFs by identifying hazards and exposures (risks) for the myriad of non-routine tasks performed in a facility;

- Is used where there are no SOPs, questions, unknown hazards, suspected high risk;

- Asks a worker / subject matter expert (SME) to share his / her accumulated experiential learning to identify and mitigate hazards. (In most cases, a small team may work through the process);

- Captures and details each step / element of any task;

- Identifies and pairs tasks and the hazards and exposures (risk) into ‘task-hazard pairs’; and

- Allows elimination of waste such that the goal is “acceptable risk with minimized waste” for each task.

When a management of change (MOC) program includes TaBRA, then there is an opportunity to efficiently and effectively identify hazards and reduce exposures for non-standard work.

Future blogs will help explain the myth of zero energy, zero risk, and 100% compliance and TaBRA and the process of risk identification and reduction.

For a FREE FDRsafety consultation, please contact us.

For more advice on safety, please reach out to FDRsafety.