The Myth Of Zero Energy And Its Adverse Impact On Prevention Through Design

THIS ARTICLE IS FOCUSED ON prevention through design (PTD) and why use of the term “zero energy” lockout/tagout (LOTO) for all service and maintenance tasks creates a range of adverse impacts. Examples of such impacts are:

•impeding efficient and effective equipment designs when tasks (e.g., setup, maintenance, servicing, troubleshooting) are not considered in the concept and design phases of projects because zero energy is a perceived, yet infeasible, objective for all service and maintenance,

•shutting down production for longer than necessary, and

•believing that conditions leading to serious injuries and fatalities

(SIFs) are reduced when, in fact, they are not.

The term “zero energy” is not the same as the control of hazardous energy, and is not found in any OSHA regulations or materials or in U.S. national consensus standards (e.g., ANSI).

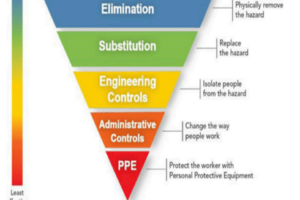

Of concern is how the concept of zero energy or a zero-energy state can negatively impact equipment design (hereafter, the term “equipment” is used to refer to machines, equipment, lines, cells, processes, etc.) because many production, service and maintenance tasks require some form of energy. The goal of PTD is to control hazardous energy to acceptable levels through a robust design process while still providing the energy necessary to perform work.

Through this article, the authors aim to prompt PTD practitioners to control hazardous energy more effectively during the design phase by better understanding OSHA regulations, ANSI standards, and rulings from the Occupational Safety and Health Review Commission (OSHRC), as well as better recognizing how to use risk assessment and determine feasible risk reduction for alternative methods to LOTO when energy is required for completing a task. This article also discusses means and methods for workers to safely perform service and maintenance tasks when energy is required.

Download the full article here.