October 2014 newsletter

- Off-the-job accidents: hidden costs to employers

- Motivating workers to be safe – 24/7

Off-the-job accidents: hidden costs to employers

By Fred Rine

CEO, FDRsafety

On-the-job accidents that result in worker deaths typically make news headlines, but for all the attention that news coverage brings to workplace safety issues, it misses an important point: more than 96 percent of fatal injuries occur outside the workplace.

Employers may be missing that point as well, losing an opportunity to keep workers safe and avoid the significant costs to their companies that come with off-the-job injuries.

The direct costs of on-the-job injuries and deaths are clear in the form of workers’ compensation claims, medical expenses, and potential legal liability. Most companies are attuned to the indirect costs as well: lost productivity, overtime, lost job experience and new employee training as well as the pain and suffering of employees and their families.

The costs of off-the-job injuries and deaths are often less obvious to employers, but can cost just as much if not more than those that occur on-the-job. Direct costs include short-term and long-term disability payments and increased health insurance premiums. The indirect costs are nearly identical to those associated with on-the-job injuries. When the greater volume of off-the-job injuries is factored in, it is clear the total cost to companies of off-the-job injuries can easily dwarf those resulting from on-the-job injuries.

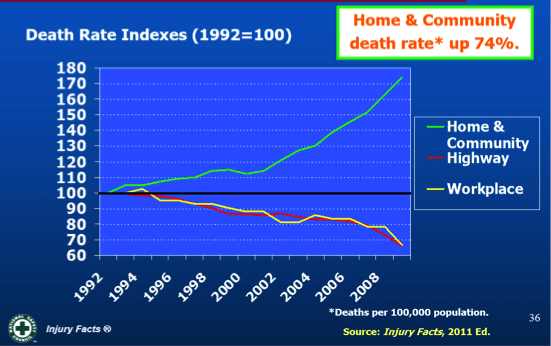

What’s more, the death rate from unintentional injuries that occur in the home and community has been increasing sharply, while the death rate from injuries in the workplace has been on a decline, as the chart below from the National Safety Council demonstrates.

This information supports the importance of investing in the safety of your employees off-the-job. For an approach to improving off-the-job safety, see the next article, which is written by Mike Taubitz, an FDRsafety senior advisor who is the former Global Director of Safety and Health for General

Fred Rine founded FDRsafety in 1996 after having served as Managing Director of Safety at FedEx, where he created its highly regarded safety program. Contact Fred at frine@fdrsafety.com or 615-370-1730.

Motivating workers to be safe – 24/7

By Mike Taubitz

Senior Advisor, FDRsafety

As an engineer and process nut, it takes a lot to get me excited about something not directly linked to systems, methods, processes, or continuous improvement.

But I have to say that one of the most effective tools I have encountered to improve safety, both on-the-job and off, is designed to impact a factor not typically addressed by engineers – human motivation.

You can create all the elegant processes in the world to enhance safety, but if an employee doesn’t want to follow them, these programs will prove to be ineffective. Figuring out how to motivate a “want to” attitude among your employees is a dramatic departure from the typical approach our profession has pushed for so long – which instructs employees that they “have to” be safe.

Two programs offered by FDRsafety – Safety Awareness and Safety Awareness 24/7 – motivate workers to want to be safe on the job and off by appealing to their sense of responsibility for loved ones. Employer-sponsored safety training has traditionally focused on the workplace, but if we value the health and well-being of our employees why would we ignore what happens off the job? Whether injured or killed at home, in the community or at work makes no difference to the family – they are still without their loved one and provider.

The Safety Awareness 24/7 program, a new offering, is focused on motivating a “want to” attitude toward safety off-the-job, while the Safety Awareness program targets the safety in the workplace. Both programs are highly interactive and consistently get high ratings from employees who attend.

To learn more, contact FDRsafety at info@fdrsafety.com or 615-370-1730.

Mike Taubitz is former Global Director of Safety and Health for General Motors.