Assessing Feasibility of Hazard Controls

This blog complements past blogs and my most recent blog about the OSHRC overturning OSHA citations regarding LOTO on Matsu presses. General Industry is now in a position to solve many of their decades-old problems with the control of hazardous energy. The answers can be determined but only after documented due diligence using Task Based Risk Assessment and assessing feasibility of hazard controls.

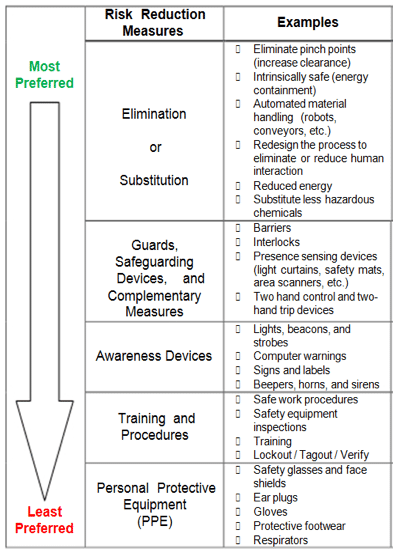

Most safety professionals are familiar with the Hazard Control Hierarchy shown below. If a higher step of the Hierarchy is not practicable, you then go to a lower step that is practicable. When elimination or substitution is not practicable, a combination of engineered controls (guards, safeguarding devices, etc.) coupled with lower order controls (Awareness, Training and Procedures and PPE) is typically used to achieve acceptable risk.

The method of determining practicability is found in ANSI B11.0 – 2015, the foundation standard for the family of ANSI B11 General Industry Safety Standards. The informative Note to the Hazard Control Hierarchy in this standard cites

Informative Note 1: Not all potential risk reduction measures are practicable. Many factors determine if the risk reduction measure is practicable. It is necessary to evaluate the application of the risk reduction measure against the following factors:

- Regulatory obligations

- Effectiveness

- Usability

- Durability and maintainability

- Ergonomic impact

- Economic feasibility

- Introduction of new hazards

- Productivity

- Machine performance

- Technological feasibility

A word of caution… You cannot simply declare that LOTO is infeasible and use control circuitry in lieu of isolating and locking the primary energy source(s). You must have a documented risk assessment, documentation of why LOTO is not feasible and validation that the controls in lieu of LOTO achieve acceptable risk.

Mike Taubitz spent many years in top positions at General Motors, including stints as Global Safety Director and Global Regulatory Liaison. He has a strong interest in lean manufacturing and its relationship to safety and in sustainability, and is recognized internationally for his expertise in machine guarding. He assists clients in creating efficient and effective safety programs, especially in manufacturing environments.

For more advice on safety, sTask Based Risk Assessment and assessing feasibility of hazard controls please reach out to FDRsafety.