Adjusting During A Pandemic: Skepticism Abounds – It Can’t Happen to Me… or Can it? Part 2

This blog utilizes research and data from a range of professional safety journals (i.e., Professional Safety) and research reports, and blends it with economic realities and common company leadership expectations. It is written as a series for those who are new to safety or have an expanded role within safety. It is meant to be easily digestible by reviewing one to two key points.

Lastly, this blog does not intend to be the end all, but is designed to mentor by overviewing basic safety program organization and key concepts.

Part 2. You can view Part 1 of this article here.

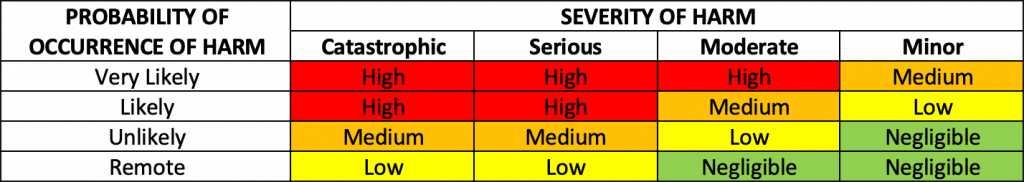

The second step is to define the consequences or the harm that may occur from an exposure to a hazard. This is where the complexity rises and driving consensus is essential. Table 2 provides one example for determining the risk for each hazard.

Table 2. Example of 4 by 4 Probability / Severity Matrix[1]

By agreeing to the probability that an event may occur and then the potential severity of the event, then the risk can be determine. Now, based on the complexity of your operation, this matrix can be made smaller or expanded. It is critical to remember the primary purpose of using Table 2 is to drive consistency between risk assessments.

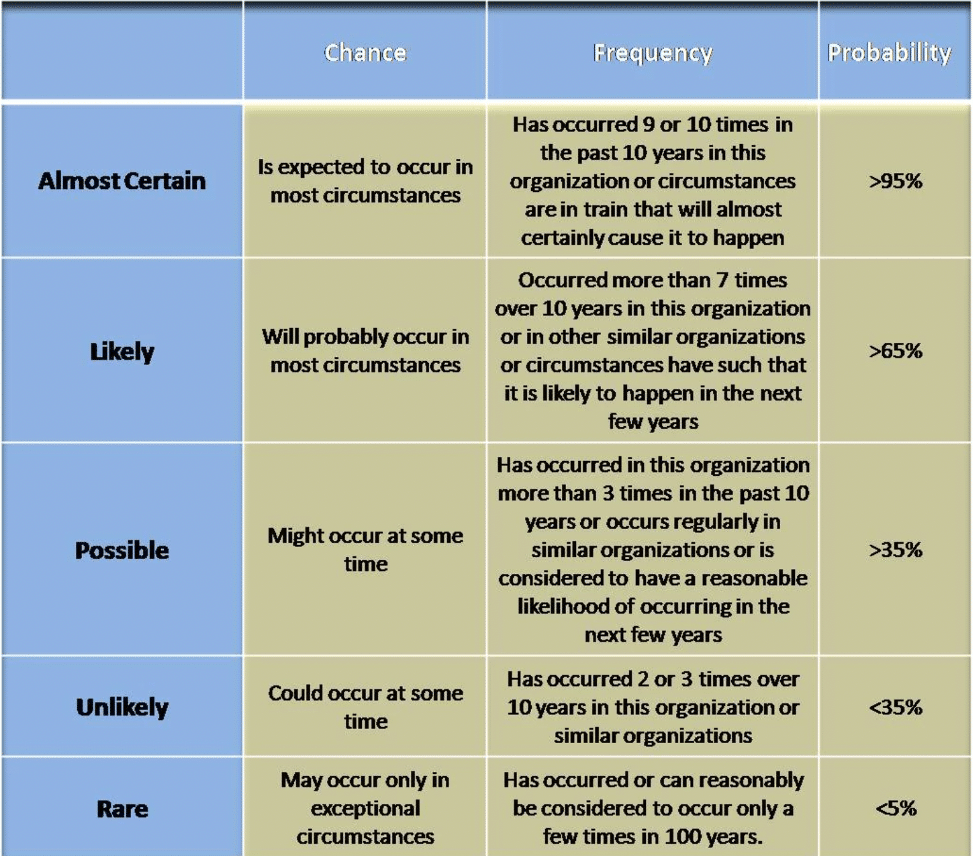

It is important to understand that there is no regulatory or legal definition for probability and severity terms. Examples of definitions are provided in Figure 3 and it is up to the team to review and edit terms for the level of risk associated with the operation(s).

Table 3. Example Definitions[2]

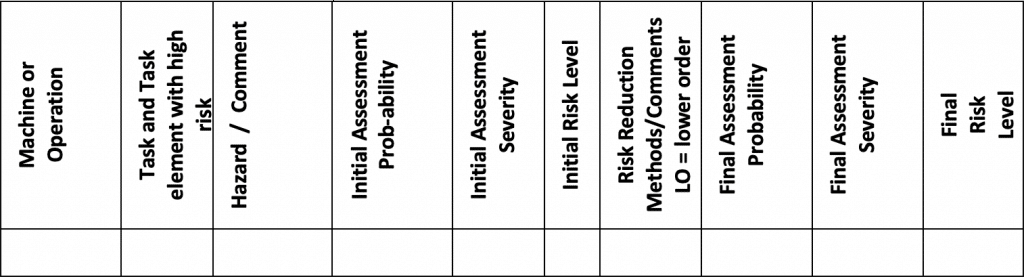

The third step is to prioritize the actions from the Risk Matrix (Table 2) to focus decision makers on the highest priority risks and actions. Table 4 provides an example layout for presenting risk data.

Table 4. Example Summary Table[3]

Once the residual risk has been established for each hazard, a decision shall be made to accept the residual risk, or to further reduce it.

As detailed by Taubitz[4], risk reduction is complete when risk reduction measures are applied and acceptable risk has been achieved for the identified hazards. Achieving acceptable risk shall include reducing the likelihood of injury to a minimum. Additionally, achieving acceptable risk shall include, at a minimum, complying with local, regional, and national regulations.

The expression “acceptable risk” usually, but not always, refers to the level at which further technologically, functionally and financially feasible risk reduction measures or additional expenditure of resources will not result in significant reduction in risk. The decision to accept (tolerate) a risk is influenced by many factors including the culture, technological and economic feasibility of installing additional risk reduction measures, the degree of protection achieved through the use of additional risk reduction measures, and the regulatory requirements or best industry practice”

Summary

In order to gain consensus on enforcement of a rule or addressing of a near miss, it helps to have consensus on the risk assessment process. To In order to gain consensus on the risk assessment process, there must be consensus on the potential probabilities and consequences (severity). Lastly, in order to gain consensus on the consequences, there must be a common recognition of the hazards.

Without this consensus, workers, manager, and executives may go in different directions on what constitutes a hazard, a risk, and the appropriate level of controls, could result in a serious injury or fatality. It will be easier to address near misses and gain acceptance of workplace rules when there is an understanding and consensus on risk and risk reduction.

The next blog will discuss the challenges and opportunities regarding the management of contractors.

[1] Lean Journey, M. Taubitz. (will clean-up footnotes later)

[2] What’s right with risk matrices? Julian Talbot, 2020.

[3] Risk Assessment and Risk Reduction Manual, Lean Journey, M. Taubitz. (will clean-up footnotes later)

[4] Risk Assessment and Risk Reduction Manual, Lean Journey, M. Taubitz. (will clean-up footnotes later)

If you have questions or need help regarding anything safety related, please reach out to FDRsafety.