FDRsafety’s Client, National Steel City, LLC Reduced or Eliminated Welding Fume Exposure and Improved Employee Comfort

The Challenges Employees Face

You are welding on the construction site and the work is rarely (actually, almost never) on a bench with ventilation. The welds must be made at working surface level, in tight spaces and in body positions that are hot and cause you to sweat.

Using a supplied air welding helmet means you might be constrained by the air hose and all the potential hazards it raises (i.e., tripping, entanglement and fatigue). Wearing a heavy backpack system means sometimes you cannot even get into the tight spaces you need to be in.

So, you are hot, tired, you may be breathing in welding fumes, and getting frustrated!

What Safety Says About Your Situation

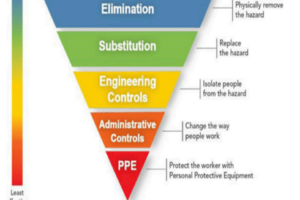

You talk to your site safety professional and he/she analyzes your situation, applies the Hierarchy of Control and evaluates the assigned protection factor (APF) for the welding to be performed.

| Hierarchy of Control Levels | Control Measure |

| 1. Elimination | Impossible, welding has to occur! |

| 2. Substitution | Impossible again, welding has to occur! The type of welding is dictated by the construction specifications. |

| 3. Engineering Control | Use of supplied air (i.e., hose or backpack) or other ventilation systems. |

| 4. Administrative Control | Welder must follow all the rules in the Hot Work Program and the Respiratory Protection Program and determine the assigned protection factor (APF). |

| 5. PPE | Welder must wear the required PPE for welding (i.e., helmet, flame retardant clothing, gloves and work boots). |

How to Reduce Your Exposure

How can you reduce or eliminate your exposure, improve your comfort and comply with the OSHA regulations?

National Steel City, LLC and its union ironworker workforce, have worked together to answer these questions. The result – use a welding helmet that combines a ventilation system and meets all the personal protective equipment and other OSHA respiratory protection requirements.

An example of this cooperative effort is the Pureflo Powered Air Purifying Respiratory (PAPR), which is designed to protect workers from welding fumes and hexavalent chromium.

This welding helmet has an electric system management (ESM), which monitors air flow with heads-up visual and audible alarms for low flow, battery and filter life. It has an air flow of 7.6 CFM with boost mode delivering over 8.2 CFM, and an APF of 1000 with no fit testing required.

Requirements for this type of helmet include, but are not limited to:

- NIOSH and ANSI certified hard hat and face shield;

- FM Approved Equipment for Hazardous Locations (certified CL I Div. 2);

- Integrated head, face, eye, and hearing protection solutions; and

- NIOSH approved HEPA filter or HE/HF for hydrogen fluoride and nuisance odor relief of most organic vapors, acid gas and ozone.

Summary

For light-to-medium duty environments, an all-in-one respirator optimized for maximum mobility may be the correct solution. By using a head-mounted design, the need for hoses and belts are eliminated, which will keep the worker safe, while simultaneously enhancing productivity.

For more advice on safety, please please reach out to FDRsafety.